Evan Lukey (left), with shift engineer Brad Barrie, monitoring the building controls at Vernon Jubilee Hospital

Among the most surprising things about the global pandemic are the unexpected lessons we’re learning as we work to keep people safe from COVID-19. For example – how something relatively small like controlling the air flow into and out of a room can have a big impact on containing the spread of the virus.

When the pandemic impacted our part of the world in March 2020, hospitals had to implement new measures for infection control. There were many unknowns about the transmission of COVID-19 and it was a priority to gain an understanding and take action to contain the virus in order to ensure continued patient and staff safety.

A quick-thinking facilities management team at Vernon Jubilee Hospital (VJH) responded by collaborating with clinical and administrative staff in designing and activating a daily air quality monitoring plan. The goal? To ensure air flow wasn’t a contributing factor in spreading the virus.

“Transmission of this new virus had raised concern for how best to protect health-care professionals while ultimately providing effective care to the patient,” said Casey Hewes, VJH director of clinical operations. “We knew that the Polson Tower wing of the hospital was designed with the ability to change air flow coming into and leaving each room via ventilation zones. So it was the best location for patients with COVID-19.”

Understanding the building’s ventilation design, the team learned how to customize the air flow, in regular patient rooms and wards, to create numerous negative pressure rooms and zones.

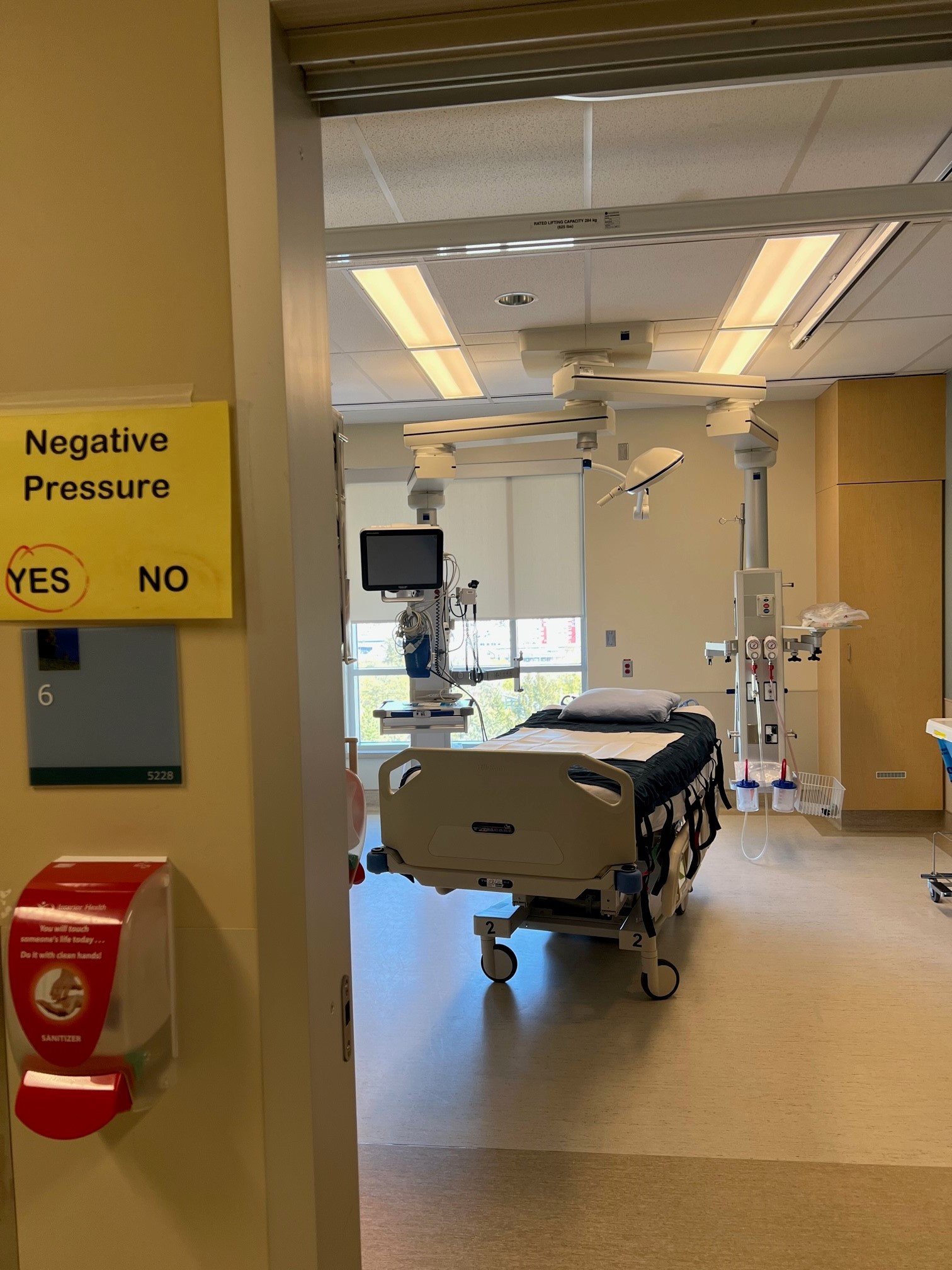

Negative pressure rooms, also called isolation rooms, are a type of hospital room that keep patients with infectious illness away from other patients, visitors, and health-care staff. It is common to isolate patients with contagious, airborne diseases.

It’s a technical process, but to break it down in simple terms, this is what it means:

Positive pressure air flow to a room results in a loss of air when doors open or close. But for negative pressure rooms, the air pressure inside the room is lower than the air pressure outside the room. When the door of a negative pressure room is opened, potentially contaminated air or other dangerous particles from inside the room will not flow outside into non-contaminated areas.

Instead, non-contaminated filtered air will flow into the negative pressure room and the contaminated air is sucked out of the room through exhaust systems with filters that clean the air before it is pumped outside of, and away from, the health-care facility.

“We had confidence in knowing we had the ability to regulate the air quality and it was a team of many who banded together to follow the new protocol,” said Evan Lukey, Vernon Jubilee Hospital Facility Manager, with Black and McDonald. “We had various tradespeople in building operations, including our HVAC technicians and power engineers, working closely with hospital administrative and clinical staff.” Black and McDonald is contracted by Interior Health to manage the facility maintenance.

The team was able to direct air flow quality through the building management system computer controls, and the temperature and humidity in a negative pressure room were also monitored for patient comfort.

“We would have daily check-ins with the clinical staff to assess how many patients there were, what rooms were needed and what daily monitoring was required,” said Evan. “We already had sound knowledge of the building’s systems but understanding when and where to place patients, and learning how to customize the building controls and assessing on a daily basis was key in ensuring everyone’s safety.”

Because the pressure in these specialized rooms has to be so carefully customized, ongoing maintenance and monitoring were extremely important so as not to result in sharp changes in the room pressure.

The team at VJH learned that remaining flexible throughout each wave of the pandemic by assessing and improving their protocols allowed for an effective response to containing the spread. It was a kind of pressure that they could overcome on their own amidst the ongoing uncertainty of the pandemic.

“We know that each building and facility is unique,” Evan added. “Black and McDonald was able to share our learnings of the advantages of Polson Tower’s HVAC design with IH’s operations managers to help influence future designs. It helps to keep us innovative.”